Testing your perimeter before Mother Nature does.

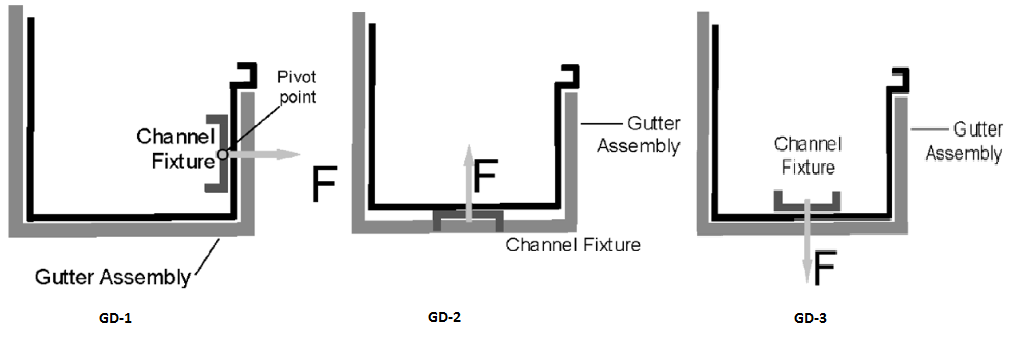

WTSC performs one or more of the following tests on your perimeter edge flashings using our fully automated ANSI/SPRI ES-1 testing machine. These three tests are detailed in the ANSI/SPRI ES-1 standard.

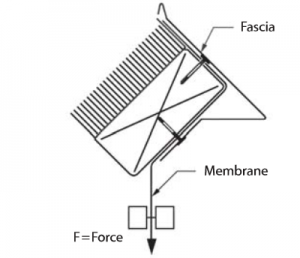

Test 1 (RE-1) tests the roof edge termination for mechanically attached and ballasted roofing systems by evaluating the perimeter attachment to ensure that it has a minimum holding power of 100 lbs/ft.

METHOD: The membrane is pulled at a 45-degree angle to the roof deck to simulate a billowing membrane. Failure is defined as any event that allows the membrane to come free of the edge termination or the termination to come free.

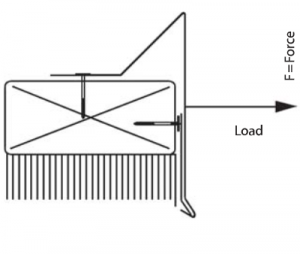

Test 2 (RE-2) is a pull-off test that evaluates the strength of the metal edge flashing to ensure that the fascia system meets or exceeds the building’s calculated design wind pressure.

METHOD: A load is applied to the fascia metal to simulate the wind load. The calculation used is: Force at Failure X Faced Area = Blow-Off Resistance. The results must meet or exceed the building’s calculated design wind pressure.

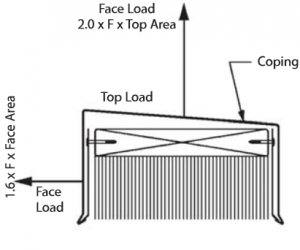

Test 3 (RE-3) is a pull-off test that evaluates the strength of the metal coping cap to ensure that it meets or exceeds the building’s calculated design wind pressure.

METHOD: A load is applied to the coping cap to simulate wind load. Simultaneous up and out forces are used. The calculated used is: Force at Failure X Face Area = Blow-Off Resistance. The results must meet or exceed the building’s calculated design wind pressure.